The Best In Quality Materials & Services

MCM Sales, Inc. specializes in providing all types and sizes of affordable industrial roll coverings, coatings, roll bodies, and heated rolls. We have the materials you need to maximize your effectiveness and improve your productivity. Contact us today by email or phone for more information about our products and services.

|

|

|

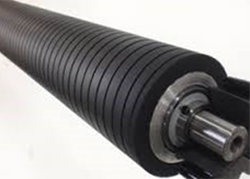

Rubber Roller Coverings

Multiple manufacturers combine to provide an unmatched line of synthetic rubber materials, including custom blend. These can be formulated to enhance the properties critical to your application. High wear proprietary materials, to include a high wear resistant Silicone, are featured.

|

Capacities = up to 80" Diameter and 480" in length. See our Featured Product page.

EPDM, Hypalon, Nitrile, Acrylic Nitrile, Carboxylated Nitrile, Natural Rubber/Polyisoprene, SBR, Neoprene, Silicone, Fluorinated.

|

|

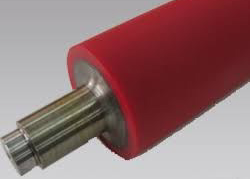

Polyurethane Roller Coverings

Mold casting and state of the art rotational casting are selections available to insure you the most satisfactory and economical coverings.

Polyester and Polyether, both available from 15 to 95 Shore A. Rotational Casting Capacity of 86" Diameter and 500" length.

|

|

|

|

|

Chrome Rollers

With over 50 years of experience our chrome partner can provide multiple plating designs with a vast variety of finishes and close tolerances.

Flawless mirror under 1 Ra, combination products - chrome over nickel, chrome-Teflon, Chrome-nickel, soft matte, hard matte, custom matte finishes, Electroless Nickel, Acid Flushing.

Capacities = 72" Diameter and 336" length to 24 Ton Weight.

|

|

|

Heated Rollers

Multiple sources are used to manufacture all types of heated rolls. Flooded rolls, double shell spiral baffled rolls, High performance double shell roll-milled channel rolls.

Featured Product - The Tokuden Jacket ™ Induction Heated Roll. The most sophisticated and accurate heated roll available. This roll has a temperature distribution uniformity of +/- 0.5° C at 250° C. See our Featured Product page for further detail.

|

|

|

|

|

Ceramic & Tungsten Carbide Coatings

A variety of spray equipment is available for material application. Included are HVOF, Plasma, thermal and wire. Copper and Nickel plating are also available.

- 3" to 40" I.D. dependent upon length

- Corona Treating Rolls

- Diamond Grinding = 66" X 375"

|

- Finishing Capabilities = 36" Lapping machine, Engine lathe 20" X 160" and 24" X 60"

- Spraying Capabilities = 72" Diameter and 420" Length

- Super Finishing = 28" X 72"

|

|

|

|

New Cores

Any one of many machine shop partners can provide you with newly constructed cores that meet your exact specifications. They can facilitate fabrication, heat treatment, finish grinding, super finishing, CNC, and dynamic balancing.

Capabilities = 72" diameter and 178" length.

Chill and Heated roll rolls of all designs. Various grades of alloy steel, alloy iron, stainless steel and non-ferrous metals in cast or rolled form. Flame, induction or carburized hardening.

|

|

|

|

|

Hardened Rolls

Our partner for hardened rolls has been supplying industry with quality heat treated rolls for over 50 years. Multiple materials, to include stainless steel, are quenched and tempered for high hardness and elevated temperature applications.

Deep case carburized, and hardening are offered with a final case depth up to 3/8" per side. Induction and flame hardening are also available.

|

|

|

Reconditioned/Core Repair

Multiple partners can be chosen to satisfy all types of roll repair and reconditioning.

- Journal Repair - Resurfacing, Welding, Keyways, Re-Machining.

- Assembly & Disassembly - Bearing Housings, Components, Drives, Clean & Degreasing.

- Regrind - Rubber, Polyurethane, Hard Coats, Tapered & Radial Crowns.

|

|

|

|

|

Non-Woven Rolls

Proprietary fiber and binder systems are used to produce a variety of purposely engineered non-woven, produced on captive lines to produce non-woven rollers. Capabilities = 86" diameter and 212" in length.

- Wringer and Squeegee Rolls

- Tension Stand Rolls

|

|

|

Release Coatings

High release Silicone based coatings are applied over a thermally or plasma sprayed layer yielding a durable coating with a wide range of surface textures. Primarily for use in the Converting Industry where durable non-stick surfaces are required. For rolls and components used in handling.

Adhesives, hot plastics and other sticky materials. Fluoropolymer coatings are also available for the best in durability, low friction, release and ease of cleaning.

|

|

|

|

|

Grooving & Special Surface Finishes

Super Finishing, Grooving, Spreader Rolls, Serrated, Diamond, Circumferential, Seamless Building, Special Properties, Teflon®.

|

|

|

|